In Casting a Mold Is Used Into Which

I have specified molds for diecasters-never used cast iron. Use a mold release to avoid binding the object and to separate it easily.

Once a resin mold has been created and a separating agent applied casting resin is poured into the mold to cure.

. To make the mold pour plaster around a clay pattern and let it set. The metal and mold are cooled and the metal object is removed and finished. A bowl of water with liquid soap 1 part soap and 10 parts water and the item you want to reproduce.

We used H-13 steel and it lasted for 1000s of shots. My understanding is that yes it can be done. Automotive parts train wheels lamp posts school bus pedals and much more.

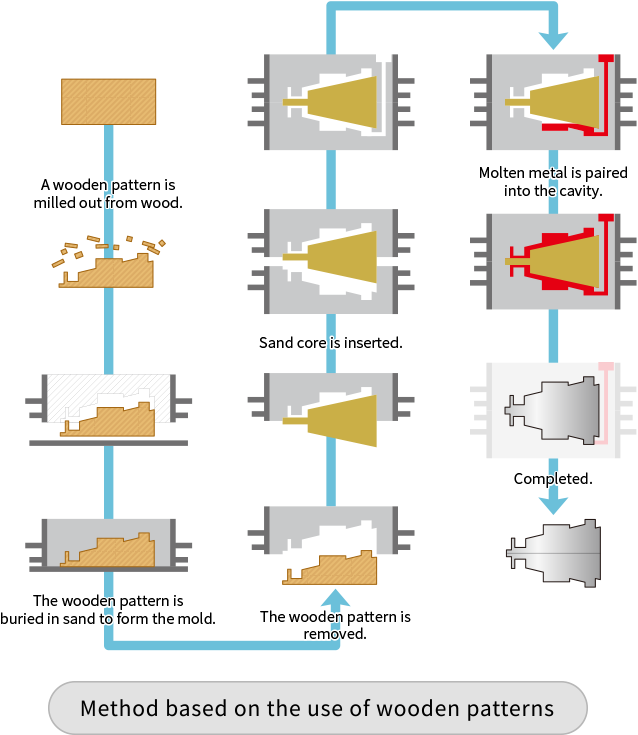

3000 bc when it was used to form most of the bronze pieces now found in museums. Sand casting is a metalworking process in foundry that uses sand as the molding material allowing for low-cost casting of unique metal shapes. The metal and mold are cooled and the metal object is removed and finished.

Then fill the mold with glass and cast it in a kiln. This is used to create the mold that should be removed from it. These methods allow foundries to precisely control the rate at which a mold fills.

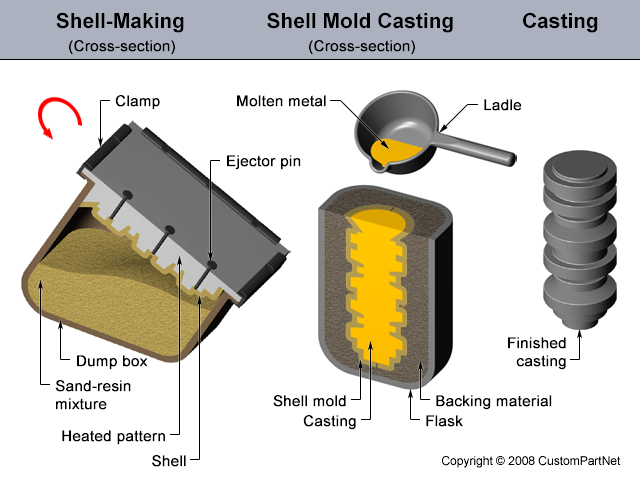

Casting is used for producing parts to near-net ie. Vacuum Casting is a casting process in which a liquid material is drawn into a silicone mold using a vacuum to create complex components. Sand casting molds are the indispensable parts in the sand casting process and play the vital role in casting a range of industry applications.

The statistics show more than 61 of all metal castings are produced by sand. These metal casting processes may be completed in a. Mold on the other hand is the hollow cavity that has been formed in order to imprint the object and take a replica out of it.

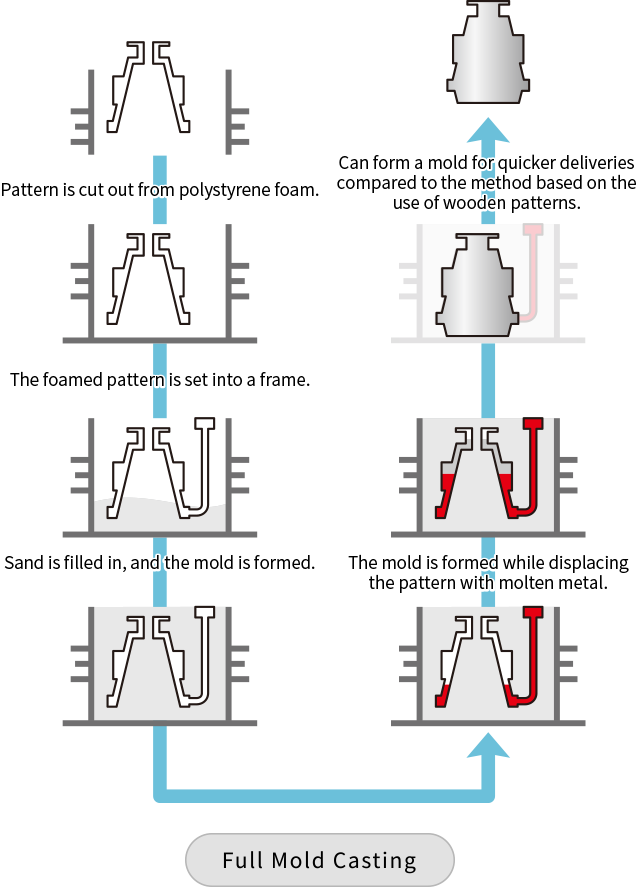

The artist produces many images to model the form usually clay wax or concrete. Casting is a technique used in sculpture in which a mold is created of the desired sculpture and then molten material is poured into the mold to create an exact replica of the original. Based on a steel-based hot-dip copper plating experiment this study simulated the action behavior of copper adhering to the surface of a continuous casting billet after mold wear and systematically.

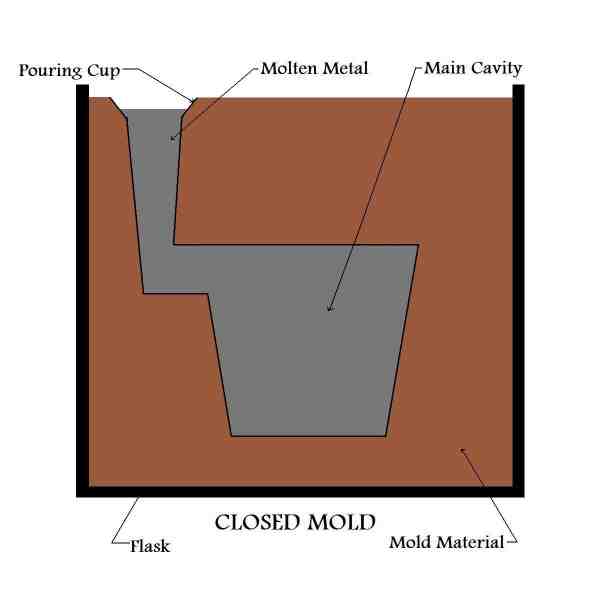

The mold itself is ready for casting. It can be used to make metal components of all sizes ranging from 1kg to hundred tons. Casting consists of pouring molten metal into a mold where it solidifies into the shape of the mold.

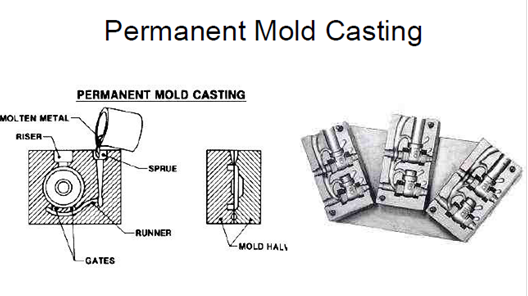

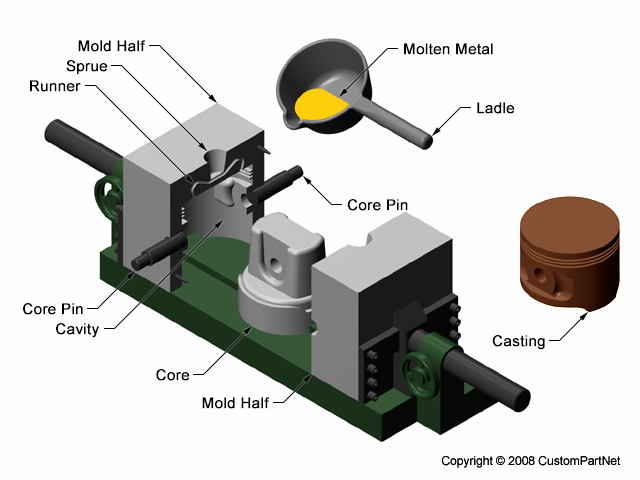

If you dont have the release agent simply soak the mold into some hot water which can effectively soften up the mold and resin. Also known as permanent mold casting it is a casting method in which liquid metal is poured into a metal mold to obtain a casting. Permanent mold casting process in which molten metal is injected into mold cavity under high pressure - Pressure maintained during solidification then mold is opened and part is removed - Dies molds in die casting - Use of high pressure to force metal into die cavity.

Metal casting is a 7000-year-old process used in both manufacturing and fine art. Main Differences Between Cast and Mold. 9 hours agoSurface cracks are easily produced after friction between continuous casting billets and copper layers in mold cavity but the formation mechanism is not clear.

Open-faced molding is used when casting pieces where one side is flat like when making a glass tile or a coaster. My further understanding is that cast iron is used so that the mold doesnt warp after the first time you pour molten aluminum into it. Permanent mold casting PMC is the process of transferring molten metal to a metal mold by the gravity assistance and ensuring that the metal solidifies in this mold.

Cast is the final product that is obtained when the casting liquid is poured into the mold and is left to harden. Its used to make many metal objects used in our daily lives. Pressure casting methods use forces other than gravity to control the flow of metal into a permanent mold.

Casting from long and skinny molds can be hard to get out try to use the mold release agent like detergent cooking oil and etc. A cast is a form created by this process. Once the plaster has solidified remove the clay and finish drying the plaster mold in the oven.

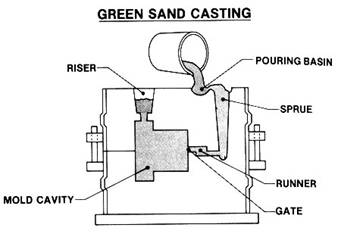

Sand casting known as sand molding casting is a casting process that uses sand as a mold. Using tubes of silicone chalks. Metal shapes are formed by pouring liquid metal into a mold where it is cooled and later extracted from the mold.

Molten metal introduced into the mold is flung against the interior surface of the mold producing a casting that can be free of voids. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. Molds are negative forms that are used to shape casting materials creating duplicates of the model object the mold was made from.

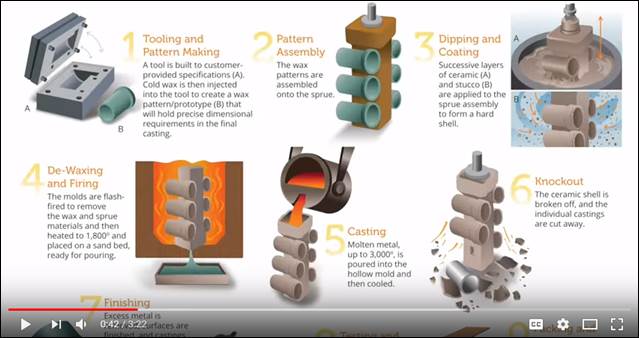

Traditional metal casting techniques include lost-wax casting plaster mold casting die casting and sand. Do not use sharp tools to peel them out in case the mold gets ruined. The resulting cast will be an exact likeness of the shape of the hollow mold form.

Most resin molds can be used multiple times to create nearly identical resin pieces especially if used with a backup mold to prevent distortion. Traditional metal casting techniques include lost-wax casting plaster mold casting die casting and sand casting to name a few. By Dinh Tien Vu Metal Casting.

Then pour the liquid metal into this mold to create a casting partIt is one of the oldest casting processes. It is particularly valuable for the economical production of complex shapes ranging from mass-produced parts for automobiles. Centrifugal casting is used to produce long cylindrical parts such as cast iron pipe by relying on the g-forces developed in a spinning mold.

Generally metal molds are made of cast iron and cast steel. The mold is made of metal and can be used repeatedly hundreds to thousands of times also known as permanent casting. The easiest example of what a mold is that almost everyone has used before is an ice cube tray.

Casting involves making mold and pouring liquid material such as molten metal plastic rubber or fiberglass into the skin. During metal casting molten metal is transferred from a crucible into a mold to create a positive metal cast object. The process was well established in the Bronze Age beginning c.

Gravity always works with the same force but man-made forces can be varied. The molds can range from very cheap sand molds to elaborately machined chromium-steel molds costing well into the 6 figure range. Casting is pouring molten liquid into a mold where it is subsequently allowed to cool solidify before ejection for use.

The mold can be cast more than. Coloring agents can be added to clear resin to change the color of the finished pieces. Vacuum casting is sometimes referred to as polyurethane casting or urethane casting as polyurethane resin a.

This can be done with a variety of materials but most commonly bronze or. The process of making a cast is known as a casting while the. Air or gas vacuums mechanical or centrifugal forces are all used in pressure casting.

If cores made of sand or plaster used in the PMC method is called as semi-PMC 68. During metal casting molten metal is transferred from a crucible into a mold to create a positive metal cast object. If you choose this method the items you need are.

Metal casting is arguably the earliest and most influential industrial process in history.

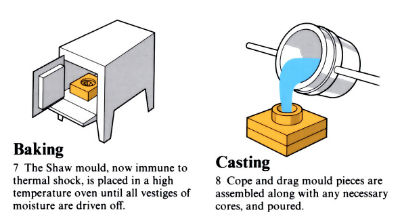

Ceramic Mould Casting Openlearn Open University

Permanent Mold Casting An Overview Sciencedirect Topics

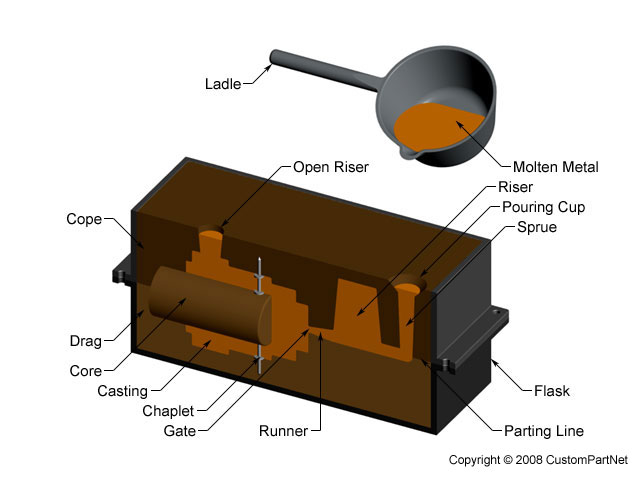

The Components Of The Sand Casting Process Manufacturing And Engineering Design Blog

Mold Making Casting Basics 6 Steps Instructables

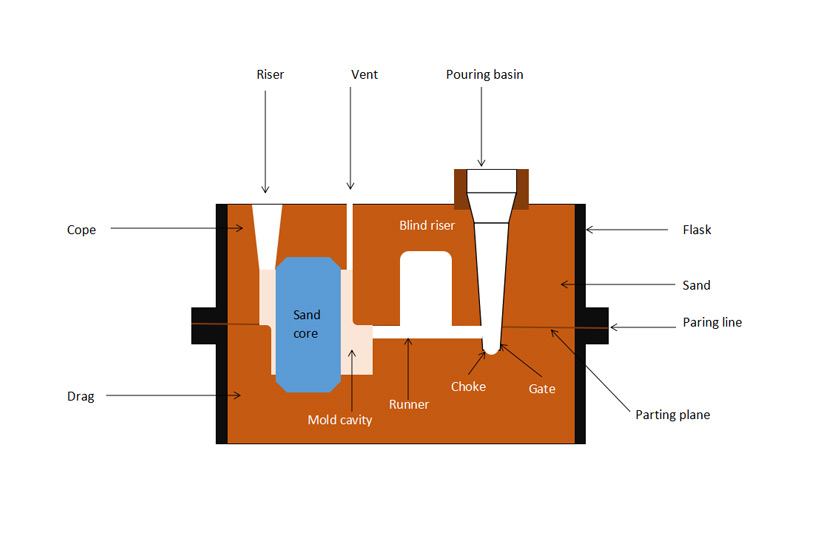

Sand Casting Process Defects Design

Sand Casting Process Defects Design

Instructions For Making Sand Casting Molds In Detail Step By Step

Permanent Mold Casting An Overview Sciencedirect Topics

Casting And Mould Making Learn Module Unsw Making

Mechanical Engineering Casting

Back To The Basics Bronze Casting Process National Bronze Manufacturing

Comments

Post a Comment